Are you ready to sprinkle some zest into your culinary adventures? Building a taco truck is not just about serving food; it’s about creating an experience that brings joy to taco lovers everywhere! This vibrant journey begins with a well-thought-out business plan that understands your target audience and unique offerings. From there, the adventure takes shape as you decide whether to purchase a ready-made truck or embark on crafting your mobile kitchen from scratch. Then comes the critical step of navigating the labyrinth of permits and licenses, ensuring your truck is legally ready to hit the streets. Finally, unleash your creativity in designing the truck itself, where functionality meets eye-catching aesthetics. Join us as we explore each of these exciting chapters, setting you on the path to taco truck success!

null

null

Choosing Your Taco Truck Path: Buying Ready-Made vs. Building From Scratch

When you set out to launch a taco truck, you stand at a crossroads that can steer your entire business arc: buy a pre-built unit or design and construct a truck from scratch. The choice is not simply about cost. It’s about speed to market, the degree of customization you need, how you plan to scale, and how deeply you want to imprint your brand on every inch of the vehicle. The decision will ripple through your daily operations, your energy use, and your long-term adaptability. The aim is to illuminate the path that aligns with your vision, not just your spreadsheet.\n\nBuying a pre-built taco truck offers a compelling combination of speed and reliability. From a logistics standpoint, a ready-made unit typically arrives with core systems already integrated: refrigeration for cold storage, cooking equipment that meets health and safety codes, a durable stainless steel shell, and a layout designed to optimize workflow from prep to service. There is a certain peace of mind in knowing the truck has been engineered to operate under the rigors of mobile vending. In practice, this means less time wrestling with fit and finish, fewer long nights chasing mechanical quirks, and more time focusing on recipes, service rituals, and the daily rhythm of a pop-up that moves with the crowd. In many established supplier networks, you can expect standardized warranties and post-purchase support that help you navigate maintenance, parts, and occasional upgrades. When a busy weekend demands a reliable turnaround, that stack of assurances can be a real asset. In markets with robust fabrication clusters abroad, there is a breadth of customization available within a pre-built shell. You can fine-tune ventilation, storage, and counter space to accommodate specific menu items such as al pastor style roasting or multi-sauce setups, while still preserving the structural integrity and compliance framework built into the base unit.\n\nOn the flip side, a pre-built truck is rarely a perfect fit out of the box. The same efficiency that makes it appealing can also undercut your unique concept if the kitchen flow doesn’t align with your recipe cadence. If you run a menu that thrives on large, specialized equipment or you intend to push a high-volume, high-velocity service model at festivals or urban corridors, you may encounter limits that require midstream modifications. Some buyers discover that certain models emphasize dry storage or refrigeration at the expense of a generous prep zone. Others find that the counter height or window placement does not mirror how they interact with drivers and customers during peak times. There is a practical truth here: a standard configuration is a starting point, not a final doctrine.\n\nBuilding from scratch offers a compelling form of creative control. It is a chance to design a kitchen that mirrors your culinary process with surgical precision. If your concept depends on a vertical rotisserie, a compact but powerful grill array, or a solar-ready power system for off-grid events, a custom build becomes a platform for innovation rather than a compromise. This path invites you to sculpt every square inch around how you prep, cook, and serve. You can tailor the interior to maximize throughput, minimize cross-contamination risks, and streamline cleaning routines. Insulation, heat transfer, and energy management can be engineered to your climate and venue profile, so you’re not paying for air conditioning you don’t need in a mild market and not fighting heat buildup in a desert setting. A bespoke design supports a distinct brand voice that can translate visually into signage, color palettes, and a module layout that makes your truck instantly recognizable.\n\nYet the freedom to tailor comes with a heavier burden. Custom builds demand meticulous planning, especially around code compliance, utility integration, and long-term maintenance. You will need a clear blueprint that covers potable water supply, waste management, fire suppression readiness, ventilation, propane or electrical systems, and back-up power solutions. In addition, coordinating with fabricators, suppliers, and inspectors takes time and capital. The learning curve can be steep if you are new to kitchen design or if you are juggling multiple vendors. If your timeline tightens around a seasonal launch or a major event, the longer lead times associated with construction can be a risk you must manage. In addition to upfront costs, you should anticipate ongoing expenses for custom parts, on-site commissioning, and potential retrofits as your menu evolves.\n\nThe choice is rarely binary in practice. Many operators begin with a streamlined, semi-custom approach that blends the speed of a pre-built chassis with targeted, mission-critical customizations. You might start with a solid, compliant base unit and then add modular enhancements that reflect your signature offerings. The modular approach suits entrepreneurs who aim to expand across markets or seasons. It supports experimentation with new menu items, service formats, and energy strategies without overhauling the entire vehicle. In this sense, your truck becomes a living, adaptable platform rather than a fixed monument to a single idea.\n\nBudget is often the first argument that tilts the scale toward one path or the other. Pre-built trucks occupy a broad price band, and the lower end can be within reach for a first-time operator who wants to test a concept in a few markets. The range expands quickly once features like integrated dry storage, robust refrigeration, and high-capacity cooking lines are configured. Building from scratch can start with a relatively modest material cost, especially if you pursue a lean, efficient layout and reuse components with proven reliability. The catch is that labor, engineering, and compliance testing can accumulate quickly as you design the electrical system, water lines, drainage, and fire safety measures. The math is not just about the sticker price. It includes life-cycle cost, maintenance complexity, spare-part availability, and the risk profile of custom fabrication timelines.\n\nThe mobility and power needs of your operation also shape the decision. If your plan centers on high-footfall venues, festivals, and markets with generous power access, an electrified or hybrid layout may serve you well, and a pre-built unit can often accommodate those options with less disruption. If you anticipate operating in remote locations or during hours when access to utility lines is limited, you may value a design that emphasizes flexibility—whether that means a larger propane capacity, a generator, or an energy storage system that can sustain peak service without frequent refueling. There is also a sustainability dimension. A custom build can optimize energy use and incorporate renewable options such as solar charging for batteries, which directly affects daily operating costs and long-term environmental impact.\n\nMenu strategy and equipment capacity are the lenses through which you should evaluate the two paths. If your concept requires frequent, rapid-fire cooking of items at scale, you may demand a layout that maximizes line speed, minimizes worker movement, and reduces the risk of cross-contamination. A pre-built unit might deliver the essential reliability for this mode but could constrain you if your menu pivots toward more complex or visually dramatic preparations. A bespoke vehicle, designed around your exact workflow, can deliver that flow more precisely. On the other hand, if your menu is relatively streamlined, with a handful of core items and a few rotating specials, a well-chosen pre-built chassis may suffice and allow you to refine your service model before expanding capacity.\n\nThe regulatory landscape adds another layer of complexity. Regardless of route, the truck must meet local health department standards, fire codes, and zoning rules. Pre-built units frequently come with documentation and features that simplify compliance, such as integrated grease management and properly rated fire suppression zones. Custom builds demand extra diligence to ensure that every system—drainage, ventilation, electrical load calculations, gas lines, and safety interlocks—meets authoritative codes. The process is smoother when you partner with experienced fabricators who understand how to translate a concept into a compliant, scalable kitchen on wheels.\n\nTo bring this together, consider a practical decision framework. Start with your budget and your target markets, then map your menu and service format to the space you need. If speed to market and predictable performance are paramount, and you want to minimize risk, a high-quality pre-built vehicle with careful customization can deliver a fast, reliable entry. If your brand hinges on a distinctive cooking method or a highly energy-efficient footprint, or if you envision a future where your truck evolves with you, building from scratch offers unparalleled control. In either path, anchor your plan to the same core pillars: a solid plan for procurement and supply chains, a clear workflow design, and a rigorous focus on health, safety, and customer experience.\n\nAs you weigh the options, it helps to study models that have proven their resilience in real-life operation. Trends and case studies from bustling urban scenes show how flexible, modular thinking can yield both originality and reliability. And for operators wanting to keep their options open, a hybrid approach starting with a capable pre-built unit and layering in modular enhancements over time has become a popular middle ground. This pragmatic stance often translates into a brand narrative as well: a kitchen on wheels that is not merely a vehicle but a portable restaurant that can adapt to changing neighborhoods, seasons, and tastes. The vehicle, after all, is the stage where your culinary ideas meet the public, and the stage must be designed to support the performance you envision.\n\nWithin this framework, it is worth noting a broader ecosystem of guidance. Official resources and trade guides point to the importance of a phased approach: validate your concept with a smaller investment, learn the operational rhythms, and then decide how far you want to push customization or scale. The right path is never only about the upfront cost. It is about the confidence to execute your concept with consistency, the ability to recover quickly from hitches, and the capacity to grow with your audience. For readers who want a concise catalog of scalable models and form factors, consider exploring a curated guide to top food truck models for entrepreneurs, which offers a menu of configurations aligned with common backyard and street-market realities. Top food truck models for entrepreneurs.\n\nIn the end, you are choosing a vehicle not just for today but for the next few years of your culinary journey. Whether you lean toward purchasing a ready-made chassis or crafting a custom mobile kitchen from the ground up, you are choosing a platform that will carry your recipes, your service philosophy, and your brand identity as you roll through neighborhoods, concerts, and fairs. The best choice aligns with your target customers, your menu priorities, and your long-term plan for growth. It respects the realities of a mobile business—the need for reliable power, safe and compliant setup, and the daily dance of food, flow, and flavor. As you move from concept into concrete design, you will find that the most successful trucks are not only technically sound but also expressive of the people behind them—the cooks, the crews, and the communities they serve. And while the path to that realization can take different routes, the core aim remains constant: a clean, efficient, and welcoming kitchen on wheels that delivers great tacos, reliably, every time.\n\nExternal context that enriches this practical journey can be found in historical perspectives on the street-food movement, which trace how immigrant entrepreneurs helped shape modern culinary landscapes in many cities. For a broader historical view, see Smithsonian Magazine’s overview of the taco truck: https://www.smithsonianmag.com/history/history-taco-truck-180981278/.

The Permit Path to a Rolling Kitchen: Securing Licenses That Legally Fuel Your Taco Truck

Permits and licenses are not abstract hurdles but the scaffolding that keeps a taco truck upright, safe, and repeatable in every neighborhood you roll through. They shape every bite customers take, every hour you serve, and every mile you travel. When you view them through a practical lens, the process becomes a sequence that turns a concept into a compliant, everyday operation rather than a gamble with fines or shutdowns. This chapter walks you along that path not as a checklist of to-dos, but as a narrative of what it means to run a legal rolling kitchen with confidence, clarity, and a plan that fits your plan for flavor, speed, and community presence.

The first step is to see business registration not as a formal requirement but as the doorway into credible operation. In most cities, you’ll register as a sole proprietor or establish a small business entity, like an LLC, to shield yourself and to set expectations with suppliers, lenders, and customers. You will need to decide on a name, provide proof of identity, and declare the scope of your culinary venture. This becomes the anchor for all other permits because it ties your legal presence to your vehicle, your workers, and your compliance obligations. In some places, you’ll also register with the state, which can matter later for taxes, employment programs, and banking. The cost and the wait vary, but the philosophy is universal: establish a recognized business identity before you attempt to operate in public spaces.

Next comes the vehicle side of the equation. A taco truck is a mobile regulatory entity, and the vehicle itself must be registered as a commercial asset. You’ll need a valid title and registration in your name or your business’s name, plus a driver’s license for each person who will operate the vehicle. In many jurisdictions, there is a specialized mobile food vendor permit tied to the vehicle’s use in food service. This permit confirms the truck meets safety standards and is approved for commercial operation. Because the vehicle blends mechanical safety with food safety, the inspection process tends to be thorough and ongoing, not a one-time can’t-wait-to-get-it-done moment. Plan for technical checks, including the appropriateness of a fire suppression system, grease management, and electrical wiring that powers your hot equipment and refrigeration. Even if you’re starting with a used vehicle, the goal is code-compliant readiness rather than cosmetic polish.

The heart of your permit narrative is the health and safety framework. The food service permit, sometimes called a food establishment license, is non-negotiable for any operation that handles raw ingredients, cooked foods, and ready-to-eat items. You’ll submit plans for the truck’s layout and equipment, demonstrating that you have a dedicated cooking zone, a proper refrigeration area, a cleanable prep space, and a compliant waste disposal plan. Most health departments require you to show you have a sanitation station for handwashing and a clear method for hot and cold holding temperatures. A pre-approval review of your floor plan is common, followed by an on-site inspection once you have the equipment installed and the operation ready to run. This is the moment when a health inspector sees your system in action, checks the temperature logs, verifies cleaning schedules, and confirms that pest control is actively managed. The intent is not to trip you up but to prevent illness and protect public trust.

Alongside the food-specific permits, you’ll typically encounter a health permit process that covers personnel as well as premises. Health departments often require that every person who handles food has a valid food handler’s permit or health card. The training is usually brief but essential, focusing on safe cooking temperatures, cross-contamination controls, and personal hygiene. Keeping records of training, temperature logs, and cleaning routines helps you stay in good standing between inspections. Remember that the aim of these requirements is ongoing compliance rather than a one-off exam. It’s about creating a culture inside your truck where safety and cleanliness are as automatic as turning the key and flipping a switch.

Beyond health and business registration, a sales tax permit is a constant companion for any food vendor selling taxable goods. You do not merely collect money; you collect and remit it. The permit authorizes you to collect sales tax, which, in most cases, is then passed on to the state and local authorities. Allocating a small portion of your workflow to tax compliance from the start reduces the risk of penalties later. It also creates a transparent financial trail that can be critical when you seek financing, expand to additional trucks, or establish partnerships with events and venues.

There are additional needs that depend on where you operate and how you plan to operate. Certain jurisdictions require special event permits if you intend to sell at festivals or farmers’ markets, while others impose parking or vending site permits for specific zones. Environmental or waste-disposal permits can come into play when you’re responsible for grease management, wastewater, or large-scale trash collection. In coastal or water-adjacent districts, there may be extra rules around grease interceptors, backflow prevention, or odor control. The more you tour the regulatory landscape, the more you realize that every city treats mobile food commerce as both economic opportunity and public responsibility. A practical approach is to build a permit calendar that maps out expected renewal intervals, inspection windows, and the fees attached to each step. This calendar becomes your operational backbone, aligning the pace of growth with compliance rather than outpacing it.

Insurance, though not a permit, sits alongside these requirements as a core risk-management tool. A commercial general liability policy is typically required to protect you, your customers, and third parties in the event of an incident. Vehicle insurance tailored to mobile vendors is also common, ensuring coverage for accidents, theft, or equipment damage. Some municipalities require proof of insurance before issuing or renewing permits, so securing coverage early is wise. The policy also has a practical upside: peace of mind that lets you focus on cooking, service, and community building rather than worrying about a single mishap derailing your plans.

The practical rhythm of obtaining permits is best understood as a cooperative process with local authorities. Start by contacting your city or county business licensing office to obtain a definitive list of required documents and fees. The list you receive will reflect your location, the vehicle type, and your intended hours and routes. Always rely on official channels for the forms and instructions, and be prepared for a few surprises along the way. In some places, you may need to submit paper copies of documents; in others, online submissions are the norm. The important thing is to keep everything organized, consistent, and easy to update as your business changes. Gather each piece of evidence steadily: proof of identity, business name registration, vehicle title, driver licenses, floor plan, equipment specifications, sanitation plan, employee permits, insurance certificates, and any site-specific permissions.

A recurring theme in this permitting journey is the importance of early, proactive communication. Rather than waiting for an inspector to knock on the door with a list of deficiencies, you can preempt many issues by presenting well-thought-out plans and a transparent record system. For example, you can attach your kitchen layout with clearly labeled zones for prep, cooking, and serving, signpost where the handwashing station is located, and provide a temperature log template for the first 90 days of operation. If you’re unsure about a particular requirement, a short consult with the licensing office can save weeks of back-and-forth correspondence. The objective is not to conquer the process in a day but to cultivate a reliable, auditable system that scales as you add more trucks, more cooks, and more events.

The branding of your truck intertwines with permits in subtle, practical ways. You will design signage, a customer-facing window, and a small footprint of space that must align with the safety and sanitation standards inspectors expect. Durable, non-slip surfaces, easy-to-clean countertops, and strategic placement of waste and cleaning supplies are not mere conveniences; they are compliance-friendly choices that simplify inspections and reduce risk. Your permit journey thus becomes a design brief as well as a regulatory checklist. If you approach interior and exterior design with this dual lens, you’ll find that the aesthetics you crave—clean lines, vibrant branding, and a welcoming window—can coexist with, and even support, the strictures that keep your operation lawful and sustainable.

An additional practical thread is the collaboration with a licensed vendor for any necessary modifications to the truck. When you buy a used vehicle or embark on a custom build, you must ensure the modifications meet safety and health codes. Electrical, gas, and plumbing systems should be installed or certified by professionals who understand the unique regulatory demands of mobile food service. A well-documented build—with detailed schematics, equipment specifications, and compliance certificates—helps smooth the path through inspections and reduces back-and-forth timing. If you’re engaging a builder or a retrofitter, insist on a documented QA process, a clear timeline, and test results for critical components such as the grease trap and fire suppression system. In many cases, the inspector’s confidence is earned not just by the visible cleanliness of the truck but by the traceability of its components and the rigor of its commissioning.

Throughout this process, one truth remains constant: permits are not obstacles to your dream but the framework that makes it possible to deliver a consistent, safe, and legal experience for your customers. You can blend speed and craftsmanship with compliance, so long as you treat licensing as a strategic partner rather than a hurdle. The reward is a foundation that supports your daily operations without surprises. It becomes the quiet backbone of your brand—one that customers may not see, but will feel as you confidently serve fresh tortillas, sizzling fillings, and bright, smiling service. When you finally roll into a market, festival, or downtown corridor with the proper permits and a compliant kitchen on wheels, your credibility follows you like the scent of fresh cilantro in the morning.

For those who want a practical, go-to resource as you begin this journey, the city-level guidance on permits can be a reliable compass. It specifically outlines the typical steps—business registration, vehicle-related credentials, health and food-safety licenses, tax permits, and any location-specific permissions—that form the core of the permit ecosystem. You can consult the official LA page on food-truck permits to compare what is required, what to prepare, and what to expect in terms of timelines and fees. This is not a shortcut but a reality check that helps you set expectations and budget effectively. See the official guidance on food-truck permits here: food-truck permits – City of Los Angeles.

As you steward this journey, keep in mind the larger arc that your permitting process reveals. It is an education in how local governments balance entrepreneurship, public health, and street food culture. It teaches you to anticipate the choreography of compliance—where your truck parks, how long you stay, what equipment you operate, and how you present your menus in ways that are both inviting and safe. It also connects to your broader business strategy. You will design pricing not merely to cover ingredients and labor but to absorb the costs of licenses, inspections, and insurance. You will schedule events knowing the permit calendars and the expectations of the authorities who monitor your public space. And you will build a reputation for reliability: a truck that shows up fully licensed, thoroughly cleaned, and ready to serve with the same warmth that customers expect from a neighborhood taquería.

In the end, the permit path is a map with milestones rather than a maze. It guides you to a rolling kitchen that can adapt to new venues, new menus, and new communities without sacrificing safety, legality, or quality. The discipline you invest in the paperwork today becomes the freedom to focus on what you love—crafting great tacos, building relationships with guests, and growing your brand one high-traffic corner at a time. If you stay the course, you’ll find that permits, when treated as a strategic asset, accelerate your readiness, earn trust, and expand your opportunities—precisely the combination that separates a good taco truck from a beloved one.

External resource for further guidance on building a compliant food-truck business is the U.S. Small Business Administration, which offers a comprehensive guide to starting a food truck, including practical steps, timelines, and considerations for new operators. This resource complements the local permit process by providing national context and best practices for scaling a mobile food operation: https://www.sba.gov/business-guide/starting-a-business/starting-food-truck

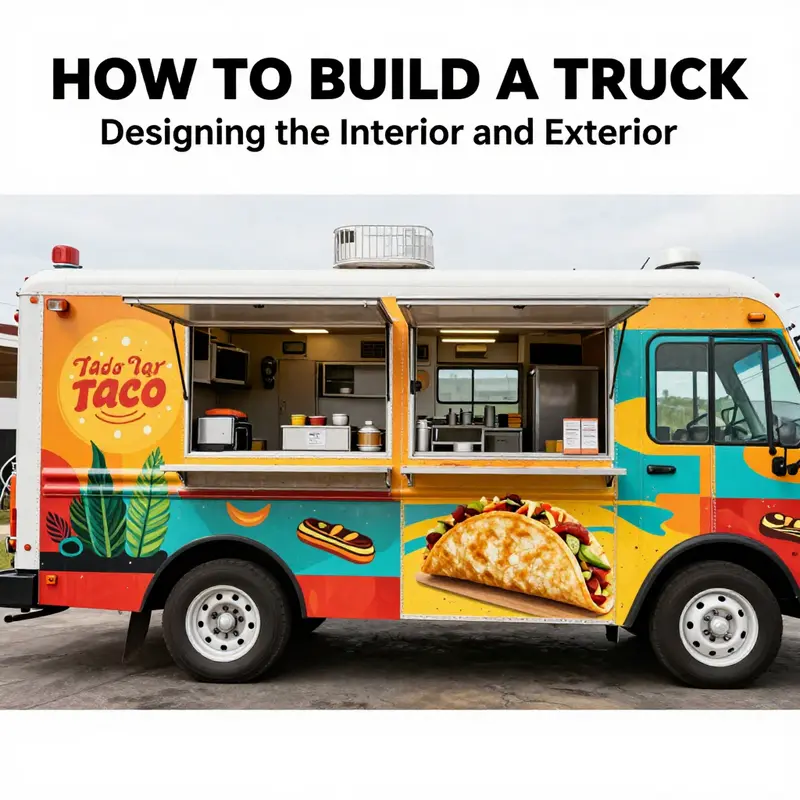

Rolling Brand, Bold Facade: Designing the Interior Rhythm and Exterior Glow of a Taco Truck

Rolling kitchens and vivid facades are not afterthoughts; they are the heartbeat of a mobile culinary venture. The process of designing a taco truck sits at the intersection of meticulous ergonomics and expressive branding. It begins with a vehicle base that can survive the road and survive the heat, then evolves into a compact kitchen that respects safety codes while inviting curiosity from passersby. The interior and exterior must converse; one informs the other, and together they create a seamless experience from the moment a potential customer catches a color in the sun to the moment a dish leaves the window steaming in a compostable cup. In practical terms, the interior is the working engine where speed and sanitation are nonnegotiable, while the exterior is the billboard and handshake that declare your concept before a single taco is plated. This duality is what separates a truck that merely feeds people from one that builds a loyal following around a story and a flavor profile.

Choosing the right vehicle base sets the tone for everything that follows. Most operators start with a sturdy cargo van or a compact box truck because these platforms offer reliable space without excessive fuel penalties. The key is a chassis that can bear the weight of a fully equipped kitchen while still fitting into the tight curb spaces of farmers markets, office complexes, and festival grounds. Once the base is chosen, the interior plan should flow with a single, logical rhythm: prep, cook, assemble, serve, and dispose. A well-ordered path reduces foot traffic jams and keeps the line moving during peak times. The best designs treat the kitchen like a performance stage where the staff can move with confidence and sightlines stay clear from the moment the first customer approaches.

Inside, the kitchen station is a central feature. A commercial-grade stove or range anchors the cooking zone, paired with a reliable fryer for items that demand crispness. The exact configuration—two burners, a compact griddle, or a mix—depends on the menu and the expected volume, but the principle remains the same: equipment must be compact, durable, and easy to clean. Stainless steel is the material of choice for countertops and walls because it stands up to heat, resists corrosion, and cleans quickly. Surrounding the stove and fryer, ample counter space provides a staging area for tortillas, proteins, salsas, and toppings. Where space allows, modular, foldable, and stackable components become invaluable. They let operators switch from high-output service to a compact, in-transit configuration without disassembling the kitchen. A deep, refrigerated prep area—whether a walk-in cooler or an under-counter unit—keeps vegetables, sauces, and dairy fresh and within arm’s reach. The goal is to eliminate unnecessary movements. If an item requires two steps to reach, that item is costing the operation time and energy.

A built-in sink with hot and cold water is not just a convenience; it is a hygiene imperative. The design should include a dedicated handwashing station that remains accessible to staff while also supporting the flow of the service window. Wastewater management is equally critical. A carefully planned waste system, with separate containers for organics, recyclables, and trash, keeps the kitchen clean and compliant with health codes. The plumbing need not be elaborate, but it must be reliable. A freshwater tank and a waste tank should be sized to support extended shifts without frequent refills. Even the smallest touches matter: slip-resistant flooring, rounded corners on workstations to avoid bruised elbows, and easily cleanable joints where two metal surfaces meet. Lighting, too, is a silent ally. Task lighting—bright, cool-toned LEDs—illuminates the prep area without generating heat that bites at staff comfort and increases the risk of heat-related fatigue during long shifts.

Ventilation is the unsung hero of any food truck. A ducted exhaust system with an efficient grease filter keeps smoke and odors moving away from the serving window and the crew, preserving air quality inside the cabin and providing a more pleasant experience for staff during long service hours. A properly calibrated exhaust also reduces the buildup of grease, which is not only a fire hazard but a constant source of cleaning headaches on the road. The interior layout should therefore position the exhaust intake and the cooking zone in a way that optimizes air movement without creating hot pockets. In tandem with ventilation, fire safety touches the backbone of the operation. A fire suppression system appropriate to the cooking appliances, along with a clearly accessible Class K extinguisher, is essential. These are not glamorous features, but they are the guardrails that allow a business to operate with confidence in neighborhoods that enforce strict safety standards.

Storage inside the truck deserves thoughtful design as well. Custom shelving, pull-out drawers, and overhead cabinets can transform a crowded space into a deceptively organized workspace. The objective is to keep frequently used ingredients within reach and to minimize the need for staff to reach over hot surfaces. Cold and dry storage should be clearly separated to prevent cross-contamination and to preserve ingredient quality during longer shifts. In addition to food storage, plan space for packaging, utensils, napkins, and cleaning supplies. A well-considered class of shelving can also double as a temporary prep surface when the line grows longer or when new menu items require additional assembly space.

The exterior design, however, is a different kind of craft—one that invites customers to lean in before they pick up their order. A bold color scheme and a cohesive logo communicate your concept in a single glance. The exterior should tell a story that aligns with the menu and the experience inside. A high-quality vinyl wrap or a durable paint job protects the surface against sun, rain, and road wear while offering a canvas for your brand. Large, illuminated signage is crucial, especially in low-light environments. The sign should be legible from a distance and not overwhelm the vehicle’s overall silhouette. Clear, easy-to-read menu boards placed on the sides or at the front help customers understand options before they step forward to order. For dynamic menus, consider digital displays that update prices and daily specials with minimal effort.

A retractable awning provides shade during the hottest days and adds an extra layer of color to the vehicle’s profile. The service window is the main interface between kitchen and customer, and its design deserves particular attention. A secure latch and screen help keep the interior secure while allowing easy access for the cashier and the cook to communicate with the customer. A rear staff door facilitates smooth movement between the kitchen and any storage or loading areas behind the truck. The exterior touches extend beyond utility; they are opportunities to reinforce the brand. A carefully chosen color palette, logo placement, and a signature motif can make a taco truck instantly recognizable in a sea of street-food options.

In moving from concept to concrete, many operators mirror techniques from larger food businesses but adapt them to the micro scale. Durable, non-slip flooring, heat-resistant countertops, and moisture-resistant wall panels protect the interior under daily wear. Electrical grounding must be wired with care to support all equipment safely. If the truck relies on a generator or battery-powered systems, plan for redundancy so that a single failure does not halt service. The interior should also accommodate a reliable power source for the POS system and lighting, plus a back-up plan for refrigeration during long festivals or events. The goal is not to chase every possible gadget but to secure a dependable backbone that ensures service remains smooth across different environments.

A crucial part of the exterior dialogue is the menu presentation. Menu boards should be legible from a distance and designed with the same color language as the truck’s graphics. Dynamic updates—whether through a simple chalkboard at the window or a digital display—allow operators to adjust offerings for seasonal ingredients, supply changes, or crowd preferences. A well-designed exterior also pays attention to practical details that influence the customer experience. A generous service window that opens to the right height for line cooks, integrated lighting for night service, and weatherproofing that keeps utensils dry all contribute to faster service and happier customers.

To connect interior efficiency with exterior storytelling, consider a small but meaningful integration: a link between the truck’s design and its online presence. A few lines of copy in the graphic language, paired with a single, well-lit callout about a signature taco or a fresh daily special, can pique curiosity. This approach complements the social-media footprint, where location updates and real-time posts showcase the truck’s current location and the day’s offerings. For a concrete example of how the field has balanced design and operation at scale, many operators study top models in the space—an accessible reference point that can guide decisions without copying a brand. You can explore this idea in depth here: taco trucks unleashed: top 5 models for culinary success.

Even when pursuing a bold exterior and a sleek interior, the reality remains that design decisions must harmonize with compliance. Local health departments often provide clear checklists for mobile vendors, detailing how walls, floors, and ceilings should be finished, how ventilation and grease management must function, and how electrical systems must be protected and grounded. The exterior is not only a canvas for branding but a shield that keeps rain off electrical housings and wind from scattering utensils. The interior layout should be planned with the same degree of care you would give a fixed-location kitchen, minus the extra square footage. In practice, this means designing with flexibility. A well-made service window, for example, should function across a spectrum of weather conditions, with a seal and frame that minimize heat exchange and keep the cold air from the prep area from drifting into the customer zone.

As you visualize the truck’s life on the road, remember that the best designs are the ones that feel intuitive to the team that operates them. The crew should be able to transition from prep to service without retraining or swapping tools mid-shift. Lines of sight should be clear so a cook can monitor the window and the pass-through without stepping back into the hot zone. The branding should work as hard as the cooks do—creating a stage set that catches the eye even when the truck is parked in the shade or tucked away behind a crowd of tents. The overarching aim is to make the truck a living, breathing expression of your menu—one that invites people to stop, look, and order because the interior and exterior feel like they were built for the moment they arrive.

Inspiration for these choices often comes from a mix of functional showcases and aesthetic experiments. Few mobile food operators tolerate bland, cookie-cutter surfaces; instead, they push for details that make the vehicle a character in the street food narrative. Consider texture and finish—diamond-plate doors, heat-resistant coatings, and carefully chosen edge detailing can convey a sense of durability and care. Color and typography should be legible from street level, and the branding must remain coherent under streetlight and sun alike. The interior’s workflow and the exterior’s storytelling are two sides of the same coin: one ensures that service is fast and safe; the other ensures that the business is memorable. This integrated approach is what turns a taco truck from a mere vendor into a mobile destination.

For readers curious about broader social and cultural dimensions that shape these designs, researchers point to the historical arc of the taco truck as a symbol of immigrant entrepreneurship and street-food innovation. While the journey spans decades and geographies, the core lesson remains constant: authenticity paired with thoughtful design yields lasting resonance on the street. As you prepare to bring your own concept to life, remember that your interior and exterior are not separate elements but a single, continuous response to the needs of your customers and the realities of the road. If you’d like to explore a broader cultural perspective that informs this craft, you can consult external scholarship on the history of the taco truck.

External reference: Smithsonian Magazine’s exploration of the taco truck’s history provides context for how street-food culture evolved in American cities and the role immigrant entrepreneurs played in shaping this culinary form. https://www.smithsonianmag.com/history/history-taco-truck-180981278/

Final thoughts

Embarking on your taco truck journey is not just about food; it’s about bringing people together through a shared love for vibrant flavors and community experiences. Each step—developing your business plan, choosing the right vehicle, obtaining permits, and designing your space—matters immensely. By laying a solid foundation and embracing the vibrant culture of tacos, you’re not just building a mobile kitchen but a platform for connection and joy at every event or street corner. So gather your ingredients, get inspired, and hit the road; the world is waiting for your taco truck!